Regular maintenance is key to keeping your boiler running efficiently, reliably, and safely. The annual shutdown is a perfect time to identify potential problem areas that need attention. To help you get started, here is an inspection checklist:

- Inspect all of the equipment in the boiler room. Walk around the boiler before looking inside. Check for “hot spots”, which may indicate compromised insulation or gasketing. Look at external piping, valving, feed system, pumps, and pump seals, and note any leaks. Listen for bearing or cavitation noise. Check the alignment of the pumps, motor assemblies and water softener.

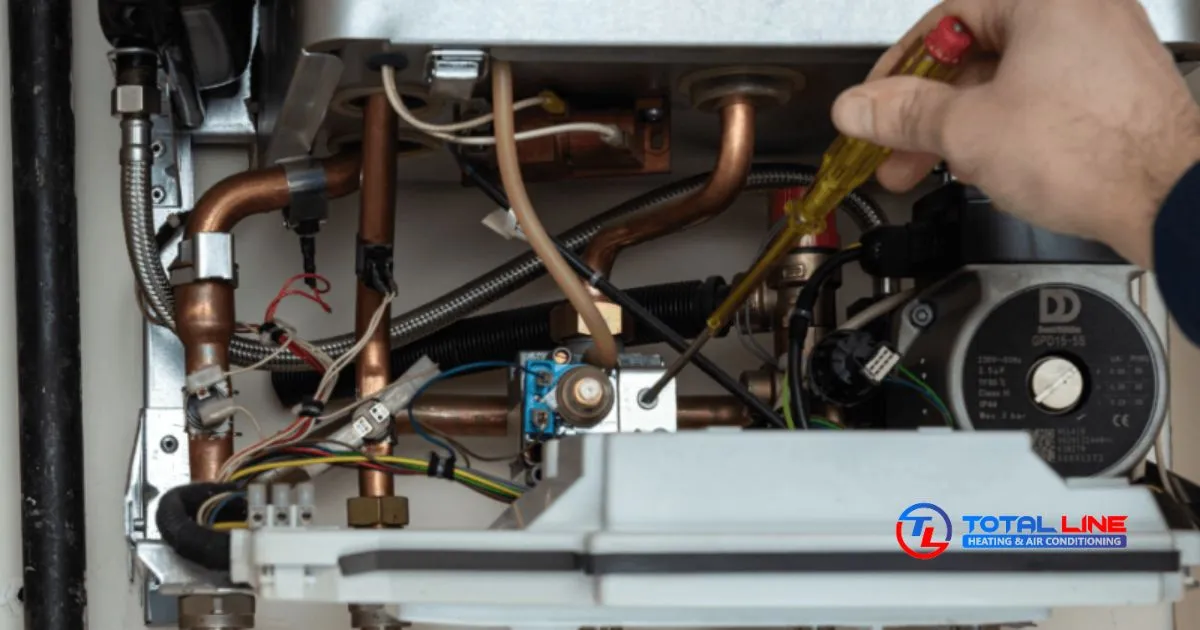

- Turn off the boiler and make sure it is secure. Look for signs of scaling or corrosion on the waterside of the boiler after it has been opened, and clean or replace tubes as needed. Examine the gasket condition on the fireside and, if necessary, replace any that are dried out, brittle, or cracked. On the refractory door look for fractures.

- Inspect the burner-drawer assembly and burner housing. With the latter, you are trying to find any telltale signs of heat damage like cracks or warping. If there is cracking, bending, or deformation of the burner baffle or diffuser then that needs to be replaced as it is essential for correctly blending fuel and air.

- The pilot tube holds the spark electrode that will create a pilot light. If this area is corroded, burned, or generally in poor condition, then there will not be enough intensity to produce a flame.

- Additionally, take a look at the lower-water cutoff. Probe it for cleanliness and dirt; if necessary, replace the probe with a new one. Examine the wiring to make sure there are no cracks or breaks, and that terminal connections are secure.

- Last but not least, pay attention to burner management and combustion settings. If they’re ancient and out of date, consider a programmable logic controller.

While a clean and operating boiler is required, don’t forget about support systems like:

Make sure that makeup-air louvers are clean, as dirty louvers inhibit the combustion air. In addition, repair leaks in valves and fittings. Leaks require the introduction of cold makeup water into a system with additional health input and chemicals. Furthermore, ensure that chimney and flue terminations are clean and clear. Test mechanical vent systems for proper operation. An improperly operating vent system affects combustion efficiency. Finally, verify that water-testing equipment is calibrated properly and not beyond its expiration date. Improper water chemistry leads to scaling and corrosion. By keeping these systems in mind, you can maintain a boiler that runs smoothly for years to come.

It is important to have an annual boiler shutdown as part of your standard operating procedures and to have trained technicians who can perform a thorough inspection and combustion tune-up.

A skilled service technician is required for boiler maintenance. Call us at 604-262-9571 or send us an inquiry via info@totallinehvac.ca to schedule a consultation or inspection of your system.